AW

Customer Demand Analysis

Overall Production Capacity Analysis

Finished Product Shipment Takt Design

Takt Time TT

Pull System

Just-in-Time Production JIT

Process Capacity Analysis

Process Balanced Scheduling

Process Takt Design

Pull System

Balanced Production

Product Synchronization

Setting the Quantity of Finished Products in the Finished Goods Warehouse

Setting the Quantity of Semi-finished Products in the WIP Area

Setting the Quantity of Raw Materials in the Raw Materials Warehouse

Takt Time TT

Pull System

Just-in-Time Production JIT

Packaging, Storage Location and Layout Planning for Finished and Semi-finished Products

Packaging, Storage Location and Layout Planning for Raw Materials

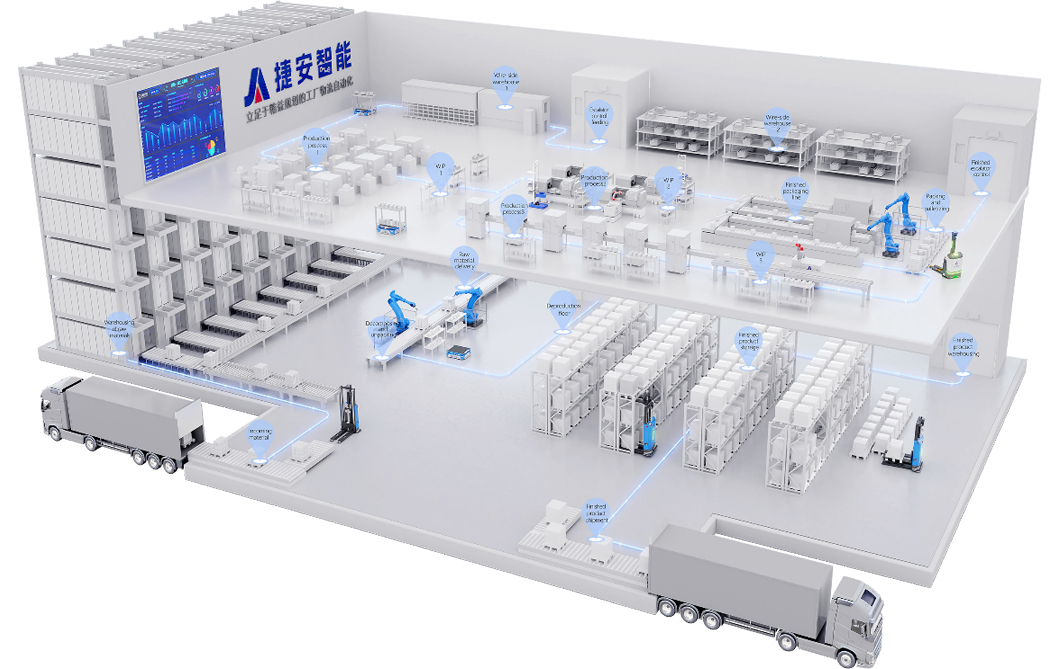

Overall Logistics Route Planning for the Factory

Visualization

Kanban

Seven-step Method 7way

Design of turnover, distribution frequency and quantity

Design of turnover and distribution containers

Design of turnover and distribution tools

First In, First Out (FIFO)

Just-in-time Delivery (JI)

Kitting

Customer demand / Production scheduling plan / Line change information

Real-time inventory status information of products

Real-time inventory status information of materials

Accuracy

Timeliness

Traceability

Manufacturing Execution System (MES)

Automation of material transfer/handling

Warehouse automation

Flexible production

Pull system

Poke - Yoke (error - proofing)

Intelligent Management System (IMS)

Equipment Dispatching System (RDS)

AGV/AMR/Intelligent Forklift/Warehouse Automatic Storage and Retrieval System

Unmanned operation

Intelligentization

Total Productive Maintenance (TPM)