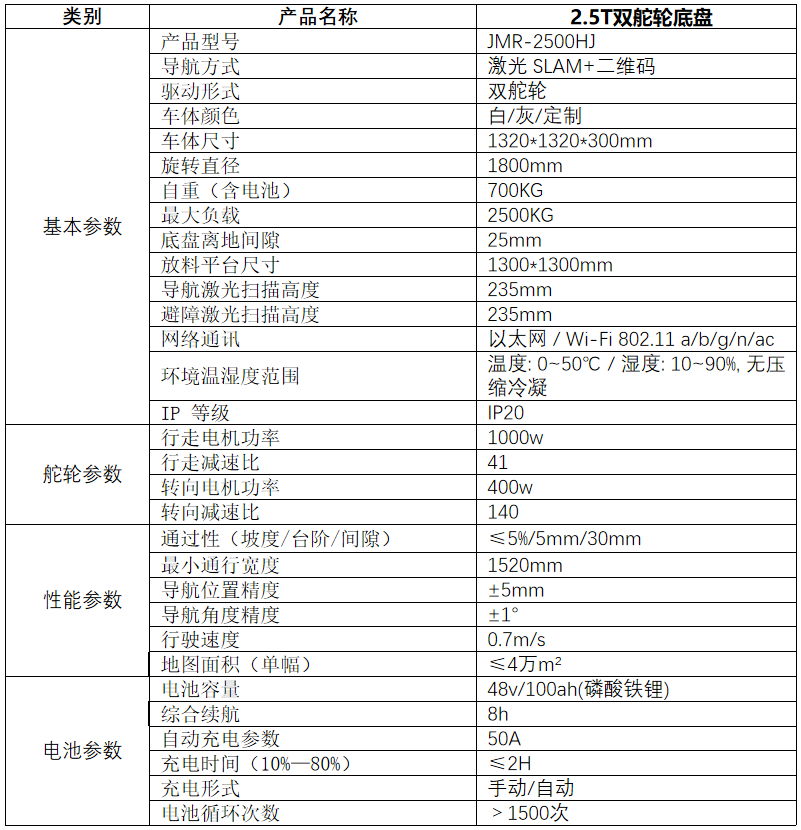

Latent jacking

Hidden Top up Series

1. 360 ° obstacle avoidance laser scanning range, equipped with various sensor solutions such as 3D camera, safe edge contact, distance sensor, etc 2. High precision recognition, precise and efficient handling, supporting identification of national, European, and non-standard pallets and pallets 3. SLAM navigation, precise and convenient, narrow lane application, slim figure, small turning radius 4. ± 10mm precision SLAM navigation, no reflector, 5. Convenient deployment, flexible scheduling, seamless access to scheduling system 6. Comprehensive protection: 3D camera plane 360 °+front space protection, obstacle avoidance laser, distance sensor 7. Charging for 2 hours, comprehensive battery life ≤ 8 hours

The hidden top lifting AGV adopts laser SLAM navigation and has a hidden function, which can flexibly and easily hide at the bottom of shelves, material carts, etc. It can dock with material carriers and achieve automatic handling without affecting the normal work of other equipment and personnel. The AGV lifting device can accurately dock with shelves, material trucks, etc., ensuring the stability and safety of goods during transportation. The load-bearing capacity of the lifting device varies depending on the model and application scenario, and can generally reach a load of several hundred kilograms or even higher. In terms of safety protection, it is equipped with various sensors such as laser radar to monitor the surrounding environment 360 ° in all directions, and can detect obstacles in various directions such as front, rear, and side in real time. Automatic charging function: When the AGV's battery level is below the set threshold, it will automatically travel to the charging area for charging. The charging methods include manual, automatic, battery replacement, and other forms. After charging is completed, the AGV can automatically return to its work position and continue to perform tasks, ensuring 24/7 uninterrupted operation and improving the efficiency of equipment use.

Application scenarios

Material transfer and expansion applications within factories, between production lines, and between production lines and warehouses: It can be seamlessly integrated with other machines, production lines, material racks, etc. by installing translation mechanisms on mobile platforms according to product form.

Applications

Can meet the needs of various industries, identify various shelves/material trucks, and drill into the bottom of shelves/material trucks to lift and transport them

Applicable shelves

Suitable for standard pallet racks, shelves, material trucks, cage trucks, etc., with a load capacity of up to 800kg and above: